Ingenieria asistida por ordenador

3 10 2011Os pongo un ejemplo de calculo de fatiga realizado con ansys versión clasica.

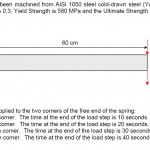

Datos:

(Go to Main Menu)

Preprocessor

Element Type

Add/Edit/Delete

Add

Structural & Solid & Quad 4 node 42 & OK

Material Props

Material Models

Structural

Linear

Elastic

Isotropic

EX = 210e5

PRXY = 0.3 & OK

Modeling

Create

Areas

Rectangle

By Dimensions

(Click X1 box) 0 (Click X2 box) 60

(Click Y1box) 0 (Click Y2 box) 1 & OK

Meshing

Mesh Tool

Click on the Lines Set button

Pick lines 2 & 4 & Apply

NDIV = 4

SPACE = -2 & Apply

Pick lines 1 & 3 & Apply

NDIV = 30

SPACE = -2 & OK

Click the Mesh Button

Pick All & OK

Solution

Analysis Type

New Analysis

Choose Transient & OK & OK

Sol’n Controls

Basic Tab

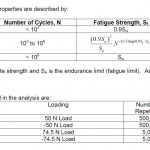

Time at end of loadstep: 10

Transient Tab

Choose Stepped Loading & OK

Define Loads

Apply

Structural

Displacement

On Lines

Pick line 4 & OK

Select All DOFs

Displacement Value = 0 & OK

Force/Moment

On Keypoints

Pick keypoints 2 & 3 & OK

Direction of Force/Moment: FY

Force/Moment Value: 50 & OK

Load Step Opts

Write LS File

Load step file number n: 1 & OK

Analysis Type

Sol’n Controls

Basic Tab

Time at end of loadstep: 20 & OK

Define Loads

Delete

Structural

Force/Moment

On Keypoints

Pick All & OK

Apply

Structural

Force/Moment

On Keypoints

Pick keypoints 2 & 3 & OK

Direction of Force/Moment: FY

Force/Moment Value: -50 & OK

Load Step Opts

Write LS File

Load step file number n: 2 & OK

Analysis Type

Sol’n Controls

Basic Tab

Time at end of loadstep: 30 & OK

Define Loads

Delete

Structural

Force/Moment

On Keypoints

Pick All & OK

Apply

Structural

Force/Moment

On Keypoints

Pick keypoints 2 & 3 & OK

Direction of Force/Moment: FY

Force/Moment Value: 74.5 & OK

Load Step Opts

Write LS File

Load step file number n: 3 & OK

Analysis Type

Sol’n Controls

Basic Tab

Time at end of loadstep: 40 & OK

Define Loads

Delete

Structural

Force/Moment

On Keypoints

Pick All & OK

Apply

Structural

Force/Moment

On Keypoints

Pick keypoints 2 & 3 & OK

Direction of Force/Moment: FY

Force/Moment Value: -74.5 & OK

Load Step Opts

Write LS File

Load step file number n: 4 & OK

Solve

From LS Files

Starting LS file number: 1

Ending LS file number: 4

File number increment: 1 & OK

(Go to Main Menu)

General Postproc

Read Results

By Pick

Select Set 1 & Read & Close

Steps to perform the Fatigue Analysis

Definitions used in performing a fatigue analysis:

Location: a node in the model for which fatigue stresses are to be stored.

Event: a set of stress conditions that occur at different times during a unique stress cycle.

Loading: one of the stress conditions that is part of an event.

(Go to Main Menu)

General Postproc

Fatigue

Property Table

S-N Table

(Click N1) 10 (Click S1) 62.1e3

(Click N2) 1000 (Click S2) 62.0e3

(Click N3) 10000 (Click S3) 51.2e3

(Click N4) 100000 (Click S4) 42.2e3

(Click N5) 1000000 (Click S5) 34.8e3

Stress Locations

NLOC = 1

NODE = 65 (node along the surface at the fixed end of the beam

TITLE = Fixed End & Apply

NLOC = 2

NODE = 54 (node along the surface in the middle of the beam)

TITLE = Middle & Apply

NLOC = 1

NODE = 32 (node along the surface at the free end of the beam)

TITLE = Free End & OK

Store Stresses

From rst File

NODE: 65

Event: 1

Loading: 1 & Apply

NODE: 54

Event: 1

Loading: 1 & Apply

NODE: 32

Event: 1

Loading: 1 & OK

Read Results

By Pick

Select Set 2 & Read & Close

Fatigue

Store Stresses

From rst File

NODE: 65

Event: 1

Loading: 2 & Apply

NODE: 54

Event: 1

Loading: 2 & Apply

NODE: 32

Event: 1

Loading: 2 & OK

Read Results

By Pick

Select Set 3 & Read & Close

Fatigue

Store Stresses

From rst File

NODE: 65

Event: 2

Loading: 1 & Apply

NODE: 54

Event: 2

Loading: 1 & Apply

NODE: 32

Event: 2

Loading: 1 & OK

Read Results

By Pick

Select Set 4 & Read & Close

Fatigue

Store Stresses

From rst File

NODE: 65

Event: 2

Loading: 2 & Apply

NODE: 54

Event: 2

Loading: 2 & Apply

NODE: 32

Event: 2

Loading: 2 & OK

Assign Events

NEV = 1

CYCLE = 500000

TITLE = Load 1 & Apply

NEV = 2

CYCLE = 5000

TITLE = Load 2 & OK

Calculate Fatig & OK

Results:

Location: 1 Node 65 at the fixed end.

The combination of event 2, load 1 and event 2, load 2 produces an alternating stress intensity of

55744 N/cm2. The spring was subjected to 5000 cycles while from the S-N Table, the maximum

number of cycles allowed at that stress intensity is 3595. The partial usage value, 1.39063, is the ratio

of cycles used/cycles allowed.

The combination of event 1, load 1 and event 1, load 2 produces an alternating stress intensity of

37412 N/cm2. The spring was subjected to 500,000 cycles while from the S-N Table, the maximum

number of cycles allowed at that stress intensity is 421,300. The partial usage value, 1.18669, is the

ratio of cycles used/cycles allowed.

The Cumulative Fatigue Usage value is sum of the partial usage factors (Miner’s rule).

Autors: Nyquist / Haghighi