Procesado de polímeros

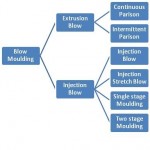

2 05 2012Types of Blow Moulding

There are two types of blow moulding – Extrusion & Injection blow moulding. In Extrusion Blow Moulding, plastic resin is heated up to melt and extruded into a tubular shape called Parison. This Parison is then trapped inside two halves of the required mould and blown by air to the shape of mould. In Injection Blow moulding, first the material is injected to form a preform and then it is blown to the shape. Extrusion Blow moulding is used to produce all types of drums, cans, bottles etc. and injection blow moulding is used to produce bottles.

Continuous Type Blow Moulding:

In continuous blow moulding the Parison – tubular molten raw material – is extruded continuously and the mould moves sidewards after receiving the parison. The blowing will be done in the blowing station and the blown containers ejected. The mould will again move towards the parison and next cycle starts.

Intermittent Type Blow Moulding:

In intermittent blow moulding the molten material is stored in a chamber called accumulator and Parison is ejected intermittently during the start of each cycle. Hence these machines are known as accumulator type blow moulding machines. In Accumulator machines Parison is ejected intermittently at the starting of each cycle. During the blowing time the molten material processed by extruder is stored in the accumulator chamber on the die head.

Injection Blow Moulding:

In normal injection Blow moulding process, the Preform made by injection moulding is directly blown to the required shape of mould. The injection process allows generating better neck formation to the container.

Injection Stretch Blow Moulding:

In normal injection stretch Blow moulding process, the Preform made by injection moulding is first stretched along the axis to orient the structure and then blown to the required shape of mould. This allows creating transparent containers with very low wall thickness and better strength.

Single Stage Injection Blow Moulding:

In single stage moulding, the preform is made and immediately blown to shape in the same machine. The normal injection blow moulding is done by this process. The stretch blow moulding also done in single stage process.

Two Stage Injection Blow Moulding:

In two stage process, first the preform made like any injection mould process. The ready preform then re-heated, stretched and blown to the required shape. Here the preform making and blow moulding are done in two different machines. This process is used normally for stretch blow moulding.

Fuente: http://blowmoulding.blogspot.com.es/2009/03/types-of-blow-moulding.html.

Autor :Narayanan U M ;India. More Than 20 Years Experience In Plastic Processing Machinery manufacturing,