Os copiamos el articulo de Tarum Tampi sobre filamento de grafeno y sus posibilidades.

By Tarun Tampi On Thu, March 19, 2015 · 3D Printing, Materials, News

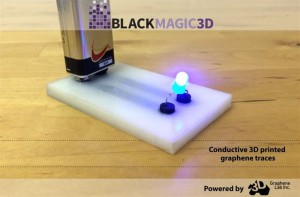

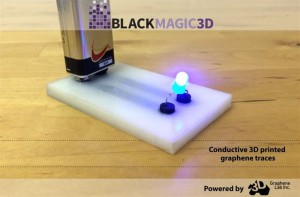

Stronger than diamonds, more conductive than copper, more elastic than rubber, and now available as a 3D printable material, Graphene has well and truly arrived, albeit as a PLA composite. The thinnest and strongest material known to mankind, infused into a PLA filament, is finally available at $65 for 200 grams. 3DPI had reported last month that the material was due for commercial release sometime in late March. As of March 16, rolls of conductive graphene filament can be purchased at blackmagic3d.com (the brand & e-commerce platform for Graphene 3D Labs Inc) for use in almost any desktop FFF/FDM 3D printer.

The release of this ‘wonder’ filament, as part of a trend of conductive 3D printing filaments and the Voxel8 multimaterial 3D printer, historically marks the beginning for 3D printing electronic devices on the desktop and is the first graphene 3D printing material of its kind. Amazingly, it can be used under the same conditions as non-functional thermoplastics like ABS and PLA.

Graphene filament opens up several design possibilities, most importantly in the creation of conductive traces, which allows you to 3D print an object and its circuitry simultaneously. Although currently, the PLA-based filament is restricted to low-voltage (less than 12V), low current (less than 100mA), and room-temperature (less than 50®C) applications, it would still find extensive use in designs for LED’s, wearable electronics, and custom electronic interfaces. Perhaps, it would also be the final key in unlocking the doors to the creation of an exhaustive and complete Internet-of-Things.

It also enables the one-step printing of other, more commonly used interface devices with conformal and embedded touch sensors. Re-designing gaming controllers, drum machines, MIDI controllers, trackpads, and digital keyboards has just become a whole lot easier. This could mean that we can expect to see a range of highly personalized, yet affordable, digital devices manufactured on-demand in the near future.

Additionally, the filament could be used to create customized EMI/RF (electromagnetic/radiofrequency) shields for crucial applications in the telecommunications, medical, aerospace, and packaging industries where it is vital to protect signals from interference by AM, FM, TV, emergency and cellular signals. Incredibly, the filament is special not just for its electronic properties but its mechanical ones as well. It has greater strength and durability than ABS and PLA, so hooks, hand-tools, drills and other tooling parts can be 3D printed for use in more robust applications.

As Daniel Stolyrov, CEO of Graphene 3D, has said, “This is an important milestone for Graphene 3D Lab, achieving revenue through the commercialization of functional 3D printing materials and in achieving the Company’s goal of building an ecosystem for 3D printing operational devices.” All in all, the release of the much-anticipated conductive graphene filament may emphatically breathe life into 3D printing.

fuente: http://3dprintingindustry.com/2015/03/19/graphene-filament-could-breathe-life-into-3d-printing/